Size

SBY-1300×6S

Features

Parameters

Composed By

Warp Feeding System

According to the fabric weight, adjust warp tension on both sides, minimize the changes of

weaving width.

Specification and dimensions are subject to change without prior notice

We always adhere to designing idea of high quality, high efficiency & low consumption, and protect the environment and promote sustained development

Model

Lay-flat width of fabric

Number of shuttles

Number of warp tapes

Weft Insertion

Power consumption

Weft Bobbin Dia.

Warp Bobbin Dia.

Bobbin size

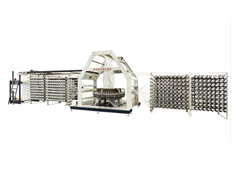

SBY-1300×6S Plastic Circular Loom

SBY-1300×6

800~1300mm

6 pcs

1176 pcs

900picks/min

5.5kw

115mm

180mm

Φ35×218mm(option)

Main Parameters

SBY-1300×6SPlastic circular loom is specially design for the high quality wide tube or flat fabric by PP or HDPE

Available : Chemical bag, Jumbo Bag, Tarpaulin etc.

• Plate cam with Grommet band & heddle wire structure, running stable, low noise, low consumption and high efficiency

• Weft break & end detecting system

• Warp feed system

• HMI central control, easy operation

Main Portion

Creel Frame

Warp break detecting System

Weft break detecting System

Central Drive system

Fabric Take-up system

Size Ring

Control system

Winder

Warp feed system

Slitting and expander

Gesseting device

The second winder

● STANDARD ○ OPTION

●

●

●

●

●

●

●

●

●

●

○

○

○

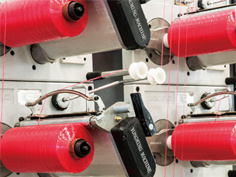

Grommet band & wire heald structure

The gromment band is made of the material with high strength and high tenacity,

combined with wire heald, stable running and low noise.

Weft breakage & weft finished detecting system

Weft breakage detection: flexible and reliable tranmission of magentic signal. Weft finished

detecting: detecting the color different between the weft bobbin and weft, once the weft

tape is nearly exhausted, the loom is stopped automatically.

Human-Machine Interface

Main motor, fabric lifting motor and warp feeding motor adopt inverter control,

advanced HMI brings convenient operation.

- Based on the concept of high rigidity, high precision, and high reliability, this machining center adopts the unique structural design of Nicolas Correa Company

(such as oversized structure, inlaid steel quenched and ground guide rails, and various configurations selected to meet different processing needs) to ensure the perfect coordination of machine tool precision, rigidity, and processing capacity.

- C5E fixed five-axis linkage head, automatic indexing head, automatic tool changer system.

- This machining center is suitable for processing various parts with large volume and high precision requirements.

- Many important core parts in our series of products are processed using this machining center. Specific parts include: T-shaped die head, wall panel, cam, oven bottom plate, etc.

- A unified standardized vertical machining center, with a simple and reliable design concept and exceptional cost-effectiveness.

- The robust structure, wear-resistant guide rails, and proprietary digital drive technology ensure high productivity and manufacturing quality.

- Can be used for workshop and production hall operations, direct supply of lathes and tool manufacturing, etc.