Parameters

SJDS

Features

Composed By

SJQS

Parameters

Composed By

● STANDARD ○ OPTION

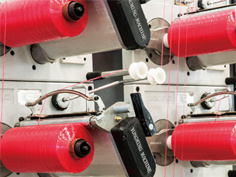

Stretching Unit

Hot air oven

Shaping Unit

Water yarn collector

Winder

DST Motor

Thermostatic control system for cooling water tank

Shaping device

Hot air oven

Water chiller

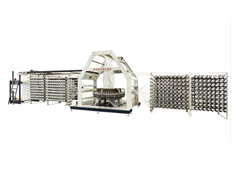

SJQS Plastic Artificial Turf Extrusion Line

●

●

●

●

●

○

○

○

○

○

主要技术参数

Stretching unit

Hot air oven

Shaping device

Waste yarn collector

Deform device

Winder

DST Motor

Thermostatic control system for water tank

Shaping device

Water chiller

SJDS Plastic Artificial Turf Extrusion Line

SJDS series Plastic Artificial Turf Extrusion Line is special design for high quality artificial turf yarn

• Available : PP, HDPE, LLDPE for production artificial turf yarn

• Multiple working position dosing blender for various material with function of data save

• Intelligentized control system with function of data save, fault alarm, central control, easy operation

• Patent technology:sufficient patents of cross, S , arch, rhombus and U type yarn production

• High precise DIE : multiple hole with flow balancing technology to offer ensurance the good quality for single yarn

90mm

250kg/h

204

72 spindles

●

○

●

●

○

○

●

●

●

●

●

Main Parameters

Material loader

Dosing blender

Extruder

Filter changer

Melt pump

Static mixer

Die

Water tank

Haul-off unit

Hot water tank

Water remove

● STANDARD ○ OPTION

70mm

180kg/h

144

36 spindles

200m/min

600-2000 denier

Specification and dimensions are subject to change without prior notice

We always adhere to designing idea of high quality, high efficiency & low consumption, and protect the environment and promote sustained development

●

●

●

●

●

●

○

○

○

○

Material loader

Dosing blender

Extruder

Auto change filter

Melt pump

Static mixer

Die

Water tank

Haul-off unit

Hot water stretching device

Water remove system

SJQS Plastic Artificial Turf Extrusion Line is special design for high quality artificial curve yarn

• Available : PP, HDPE, LLDPE for production artificial curve yarn

• Double Extruder and Double Die design for production double colour curve yarn

• High precise DIE : multiple hole with flow balancing technology to offer ensurance the good quality for single yarn

• Deform device: special hot deformation system for curve yarn high speed and quality production

65mm

120kg/h

96

12 spindles

300mm

600-1200

Main Parameters

Artificinal Turf Application:

Football, baskedall, tennis, golf, fied hockey, roof of bulidings, swimming pool, courtyard, nurseries, hotels, athletics, etc,

Screw Dia

Max. out put

Number of wires

Winder No.

Max. Speed

Tape Denier

Screw Dia

Max. out put

Number of wires

Winder No.

Max. Speed

Tape Denier

Specification and dimensions are subject to change without prior notice

We always adhere to designing idea of high quality, high efficiency & low consumption, and protect the environment and promote sustained development

●

○

●

●

○

○

●

●

●

●

●

- Based on the concept of high rigidity, high precision, and high reliability, this machining center adopts the unique structural design of Nicolas Correa Company

(such as oversized structure, inlaid steel quenched and ground guide rails, and various configurations selected to meet different processing needs) to ensure the perfect coordination of machine tool precision, rigidity, and processing capacity.

- C5E fixed five-axis linkage head, automatic indexing head, automatic tool changer system.

- This machining center is suitable for processing various parts with large volume and high precision requirements.

- Many important core parts in our series of products are processed using this machining center. Specific parts include: T-shaped die head, wall panel, cam, oven bottom plate, etc.

- A unified standardized vertical machining center, with a simple and reliable design concept and exceptional cost-effectiveness.

- The robust structure, wear-resistant guide rails, and proprietary digital drive technology ensure high productivity and manufacturing quality.

- Can be used for workshop and production hall operations, direct supply of lathes and tool manufacturing, etc.