1. Introduction to the Engineering Technology Center

1. Introduction:

The Jiangsu Provincial Multi-functional High-yield Plastic Weaving Wire Drawing Machine Engineering Technology Research Center was built in 2010. It mainly focuses on the "13th Five-Year Plan" development priorities of the national plastic machinery industry, and based on the eight major development priorities of plastic machinery tasks, combined with the company's own advantages, promotes the full-process automated production, digital monitoring, and intelligent management of plastic machinery. At the same time, it carries out research and application of the green development project of plastic machinery to achieve energy saving, noise reduction, and improve the workshop environment quality of plastic processing enterprises.

The "Center" further improves the engineering technology research center system construction, strengthens the scientific research implementation capability construction, introduces and cultivates engineering and technical personnel and scientific and technological managers, and provides a backbone team for the promotion and development of technological achievements transformation.

The "Center" vigorously promotes independent innovation and technological transformation, gives full play to and expands the enterprise's existing "specialized, refined, and special" advantages; gives full play to the advantages of scientific and technological resource integration, actively carries out engineering technology research on plastic machinery, constructs a cyber-physical system for plastic machinery manufacturing, promotes the digital design and production of the entire life cycle of plastic machinery, and improves the high-speed, high-efficiency, low-consumption, and energy-saving of equipment.

The "Center" introduces, absorbs, and innovates advanced foreign technologies, creates independent intellectual property rights achievements, accelerates the transformation of scientific research achievements, provides diversified technical services for enterprises, drives the technological upgrading and scientific and technological progress of related plastic industries, and enhances the industrial technological innovation capabilities and market competitiveness.

In the ten years since its establishment, it has 79 authorized patents, including 6 invention patents; applied for and accepted 13 utility model patents, including 3 invention patents.

2. Service Introduction:

The "Center" has gradually established an open topic management method and a production-academia-research cooperation mechanism. Combining the actual situation of the company and cooperating units, the research direction and structure of the "Center", strengthening cooperation with relevant scientific research institutes and universities, close integration with enterprises, and taking the road of production-academia-research cooperation and development, encouraging technological innovation, and promoting technological progress.

The "Center" has gradually established an open service system for all enterprises and related supporting enterprises throughout society and the industry. Free open services are provided to core supporting enterprises, and technical consulting services are provided to improve enterprises' understanding of plastic weaving machinery technology, and play a positive role in improving product quality and grade.

(1) Testing services: Using the existing testing equipment of the "Center", provide good testing and testing services for products of related supporting enterprises and similar enterprises, and conduct internal judgment on the quality of their products. For example: Greif Flexible Packaging (Changzhou) Co., Ltd., etc.

(2) Technical services: Based on the introduction of technology and independent innovation, constantly tackling major technological problems in the field of plastic weaving, providing mature technologies, processes, and products.

(3) Talent cultivation: Using the "Center" platform, a large number of mechanical, electromechanical, and other types of talents have been cultivated, and many specialized technical trainings have been conducted. Relying on Changzhou Yongming Machinery Manufacturing Co., Ltd., the cooperation network of the "Center" is built, and domestic and foreign technical exchanges and cooperation are actively carried out to enhance the strength of talent cultivation.

3. Achievement Introduction:

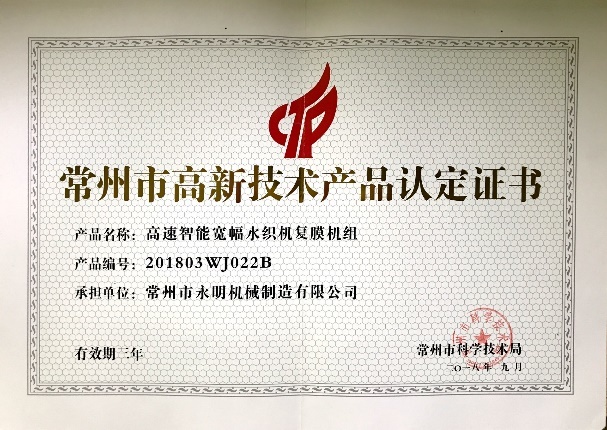

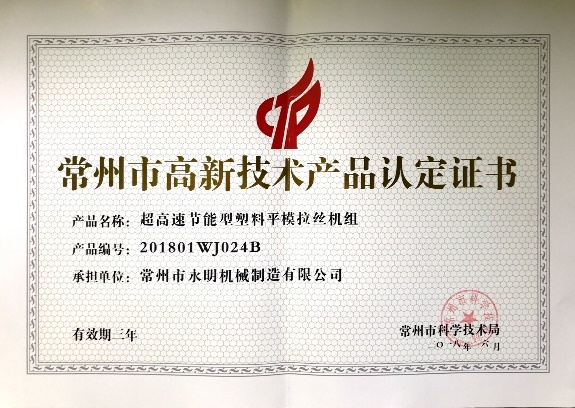

The company currently has 7 valid high-tech products. From 2018 to 2019, a total of 11 authorized patents and 13 patents were accepted, including 3 invention patents.

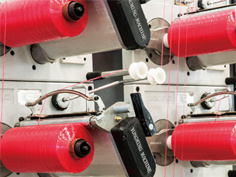

High-speed Intelligent Wide-width Water Weaving Machine Peritoneal Dialysis Machine Set

Ultra-high-speed Energy-saving Plastic Flat Film Drawing Machine Set

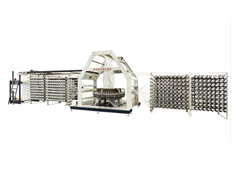

Intelligent High-speed Skilled Plastic Drawing Machine Set

Intelligent and High-efficiency Plastic Circular Knitting Machine

Novel High-efficiency Plastic Extrusion and Drawing Machine Set

4. R&D Capability Introduction:

The "Center"'s relying unit, Changzhou Yongming Machinery Manufacturing Co., Ltd., is a national key high-tech enterprise. It has undertaken many national, provincial, municipal, and district-level scientific and technological projects and has successfully completed the plans.

"Center" adheres to Yongming Company's business management philosophy - "attach importance to knowledge, gather talents widely, and entrust important tasks", insists on technological innovation, relies on technological progress, constantly tracks the most advanced technological development trends of the world's plastic machinery industry, and focuses on the research and development of plastic machinery equipment products, developing new environmentally friendly and energy-saving series of machinery products, and forming a series of specialized products. In order to better develop new projects, the company has equipped more than 150 sets of mainstream computers, established an enterprise internal local area network to achieve information sharing; using CAD, CAM, SoildWorks, etc. for product development and design, improving product R&D efficiency, shortening product development cycle, and enhancing the ability to quickly respond to the market. The company currently has more than 40 technical personnel directly engaged in the development of various products. The professional fields of technical personnel cover machinery, electrical automation, and computer applications.

"Center" invests a large amount of R&D funds every year and forms project tackling teams to overcome technical difficulties. In recent years, the company's technical personnel have successively researched and developed plastic flat film drawing machine sets, roller-type high-speed small six-shuttle circular knitting machines, and other project products, owning 12 utility model patents. The product technology level has reached the internationally advanced level, with broad market prospects and strong competitiveness.

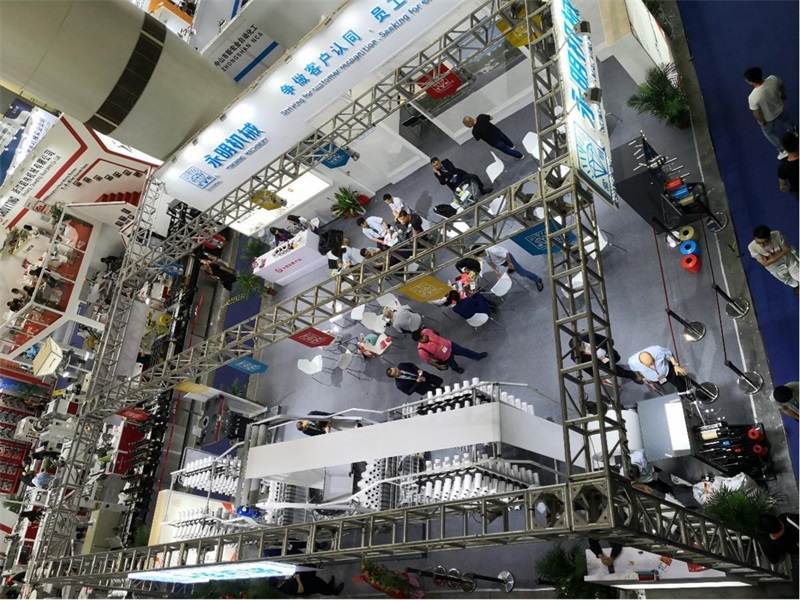

"Center" constantly enriches and strengthens the company's ability to develop new products by inviting senior experts in the plastics machinery industry to serve as senior consultants. In order to stimulate the innovation ability of researchers, product developers are also organized to participate in large-scale domestic and international plastics machinery exhibitions every year, and R&D personnel are sent to Europe, America, Taiwan, and other places for inspections and studies irregularly to enhance product development capabilities, improve product technology content, and bring broader survival space for the enterprise.

① R&D Center

② Laboratory and Training Room

③ Trial Production Center

4. R&D Capability Introduction:

Yongming Machinery participated in CHINAPLAS 2018, China International Plastics and Rubber Exhibition, and showcased the operation of the SJPL-G90×31-1200×10 plastic flat yarn drawing machine set on-site.

Yongming Machinery participated in FEIPLAS 2019 in Brazil, and showcased the operation of the SBY-1300×6 plastic cylindrical knitting machine set on-site.

III. Instrument and Testing Equipment

IV. Human Resources

Recruitment:"If you want to do a good job, you must first sharpen your tools" and "To do business, you must bring together a group of people with a sense of accomplishment and a sense of responsibility, and you must also know people and use them well, give full play to their respective expertise, bravely take on heavy responsibilities, and dare to take responsibility. The company not only focuses on absorbing professional scientific and technological talents with development capabilities from various plastics machinery enterprises, but also focuses on employing retired professors from universities and experienced technical engineers. Every year, it also recruits talents needed by the company from various universities to enrich the talent strength of various departments.

The company pays attention to the introduction of talents, but also pays more attention to the cultivation of enterprise talents, constantly tapping the potential of internal talents, and stimulating the enthusiasm and creativity of each employee to achieve a win-win result. The company actively carries out production, education, and research activities and technical exchange meetings with domestic and foreign universities and scientific research institutions. In recent years, we have also sent technical engineers to visit and learn from leading enterprises in the industry worldwide through various channels, such as Starlinger and Barmag. The company formulates training plans every year and entrusts experts from universities and research institutions and professional personnel from training institutions to conduct training for various departments and management levels of the company.

Join UsThe company has always adhered to the principle of open, fair, just, and merit-based recruitment, selecting the best candidates; the company provides a wide range of training programs, good development opportunities, and competitive salaries and benefits. We are looking forward to your joining and achieving your dreams! We also welcome you to call, write, and bring your ID card and relevant supporting documents to our company for an interview.

Company Address: No. 7, Tenglong Road, Wujin Economic Development Zone, Jiangsu Province

Company General Line:0519-86713188

HR Manager Number:13961287866

Company Fax:0519-86713388

V. Expert Introduction:

Xu Junxiang, male, born in 1970, graduated from Changzhou Machinery and Metallurgy Workers University, majoring in mechanical design, senior engineer, engaged in the research and development and management of plastic extrusion flat film drawing machine sets for 16 years. In 2008, he was awarded the honorary title of Excellent Professional and Technical Worker in Wujin District. He participated in the formulation of industry standards "JB/T5419-2008 Plastic Extrusion Flat Film and Flat Yarn Auxiliary Machine" and "JB/T5290-2008 Plastic Circular Knitting Machine".

Comrade Xu Junxiang, as the project leader, has achieved a series of achievements in product R&D work, mainly including: 1. New high-speed plastic drawing machine set, which has successively passed the appraisal by experts from Changzhou Science and Technology Bureau and Jiangsu Provincial Department of Economy and Trade, and was included in Changzhou's scientific and technological research project and the National Torch Plan project, project number: 2008GH040493. It has won the "Jiangsu Province High-tech Product Certification", "National Key New Product Certificate", and was also awarded the "Wujin District Science and Technology Progress Award Second Prize" and "Changzhou Science and Technology Progress Award Third Prize". 2. Ultra-high-speed energy-saving plastic flat film drawing machine set. This project was approved by the Changzhou Municipal Industrial Science and Technology Research Project, project number: CE2008048, and passed the acceptance.

VI. Cooperation and Exchange

1. Domestic

Yongming Machinery participated in CHINAPLAS 2019, China International Plastics and Rubber Exhibition, and showcased the operation of the SBY-850×6G plastic cylindrical knitting machine set and the double-station winder on-site.

2. Overseas

Yongming Machinery participated in the Vietnam International Plastics and Rubber Exhibition in 2017.

3. Production, Education, and Research

"Center" has established open topic management specifications and implemented a production, education, and research cooperation mechanism. Combining the actual situation of the company and cooperating units, the research direction and structure of the "Center", strengthening cooperation with relevant scientific research institutions and universities, and closely integrating with enterprises, we will take the road of production, education, and research cooperation and development, encourage technological innovation, and promote technological progress. In recent years, long-term cooperative relationships have been established with key domestic and foreign universities and research institutions such as Nanjing University of Science and Technology. Through the form of strong joint technological cooperation, strong technical support and talent guarantee have been provided for the company.

Through the strong alliance between the "Center" and universities, external experts provide technical guidance. Combining the current industry's technological development level and trends, many innovative, economical, and competitive innovations and technical know-how are proposed, ensuring the sustainable innovation and development of the "Center".

During 2018-2019, the Engineering Technology Research Center implemented a total of 2 industry-university-research cooperation projects, mainly R&D projects with Nanjing University of Science and Technology, including "R&D of strong plasticizing, low fluctuation, and low-power screws" and "R&D of parallelism correction system for peritoneal dialysis machine rollers".

VII. Technology Results Promotion and Transfer

Following the development trends of the plastics industry and the key development plan of the 13th Five-Year Plan, the "Center" undertakes independent R&D projects. In 2018-2019, the "Center" undertook a total of 5 independent research projects. By December 2019, 4 R&D projects had been completed, and all R&D projects had been transformed into products.

VIII. Patent Certificates

Do our best to help customers reduce costs and increase efficiency

Enhance competitiveness in participating in the fierce market game

Do our utmost to help customers reduce costs and increase efficiency, Enhance competitiveness in participating in the fierce market game