SJJ-G230B High Speed Inverter Winder

Parameters

SJJ-G230B

SJJ-G230B

1.5mm~6mm

400D~3000D

38mm

230mm

150m/min~500m/min

180min

20

2200mm×800mm×1800mm

Speciafication and dimensions are suject to change without prior notice.

Specification and dimensions are subject to change without prior notice

We always adhere to designing idea of high quality, high efficiency & low consumption, and protect the environment and promote sustained development

Model

Width of the yarn

Denier

Ineer diameter of bobbin

Length of bobbin

Winding speed

Max. diamater of bobbin

Quantity of winders on each frame

Dimension of frame

Main Parameters

Optional choice for the lnner diameter of bobbin and the length of bobbin

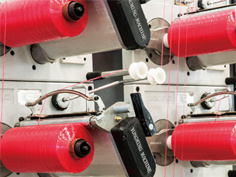

● Digital tension control, optimize the form of yarn package;

● Inverter control achieve the lowest power consumption;

● High quality yarn ensure the perfect weaving of loom;

- Based on the concept of high rigidity, high precision, and high reliability, this machining center adopts the unique structural design of Nicolas Correa Company

(such as oversized structure, inlaid steel quenched and ground guide rails, and various configurations selected to meet different processing needs) to ensure the perfect coordination of machine tool precision, rigidity, and processing capacity.

- C5E fixed five-axis linkage head, automatic indexing head, automatic tool changer system.

- This machining center is suitable for processing various parts with large volume and high precision requirements.

- Many important core parts in our series of products are processed using this machining center. Specific parts include: T-shaped die head, wall panel, cam, oven bottom plate, etc.

- A unified standardized vertical machining center, with a simple and reliable design concept and exceptional cost-effectiveness.

- The robust structure, wear-resistant guide rails, and proprietary digital drive technology ensure high productivity and manufacturing quality.

- Can be used for workshop and production hall operations, direct supply of lathes and tool manufacturing, etc.